Port Talbot is stepping up its game with the latest laser welding technology, thanks to a new partnership with German engineering experts Hugo Miebach GmbH.

The company will supply a state-of-the-art laser welding machine – a key piece of kit for Port Talbot’s new, multi-million-pound pickling line.

The new pickle line will process hot rolled coils to eliminate oxide scale formed during the steel rolling process, ensuring a clean surface for further processing, improving product quality, and enhancing the bonding of coatings or finishes.

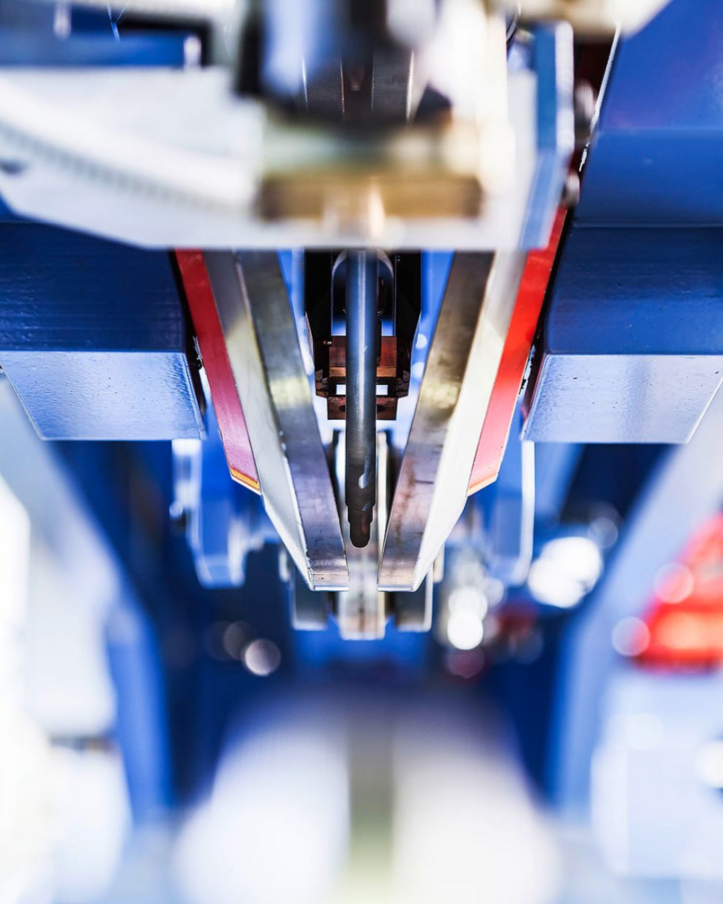

Built to handle strip thicknesses from 1.4mm to 6.2mm, Miebach's laser welder is capable of running fully automated and delivering super-fast coil changeovers with rock-solid process stability.

The weld seams are so precise, they roll seamlessly through the tandem cold rolling mill, boosting efficiency and reliability across the board.

Andrew McGregor, Programme Manager, CAPEX – Mills, said: “Our 1.8Mt cutting-edge pickling line is a critical part of steel processing and central to our wider investment in low-CO₂ steelmaking at Port Talbot.

“Bringing Miebach on board is yet another important step forward for our team of global experts delivering the pickle line. Their advanced laser welding technology will play a vital role in driving efficiency and helping lay the foundations for sustainable steelmaking in the UK for generations to come.”

It’s not just about speed and precision. Miebach’s cutting-edge technology will support the business’s wider mission to cut CO₂ emissions by 90%, part of Tata Steel UK’s £1.25 billion investment programme.

The pickling line is set to go live in 2028, marking a major milestone in the UK’s journey toward low-CO₂ steelmaking.

About Tata Steel UK

- The Tata Steel Group has been named one of the most ethical companies in the world, and is among the top producing global steel companies with an annual crude steel capacity of 34 million tonnes.

Tata Steel in the UK has the ambition to produce net-zero steel by 2045 at the latest, and to have reduced 30% of its CO2 emissions by 2030. - In October 2024, Tata Steel ceased ironmaking at its Port Talbot site and temporarily paused steelmaking pending the construction of a 3.2Mtpa Electric Arc Furnace, due to be commissioned late in 2027 / early 2028. For that period, the business will import slab and hot rolled coil to support manufacturing and distribution operations at sites across Wales, England and Northern Ireland as well as Norway, Sweden, France, Germany and UAE. It also benefits from a network of sales offices around the world.

- Throughout 2024 Tata Steel UK has been undergoing a restructuring that will reduce the size of its workforce to around 5000 direct employees, supplying high-quality steel products to demanding markets, including construction and infrastructure, automotive, packaging and engineering.

- Tata Steel Group is one of the world's most geographically-diversified steel producers, with operations and a commercial presence across the world.

- The group recorded a consolidated turnover of around US$26 billion in the financial year ending March 31, 2025.