Reducing reject rates from over 20% to near-zero, with the help of our UK Customer Technical Services (CTS) and Research and Development (R&D) teams.

Client: Gestamp

Project: Punch clearance analysis and adjustment

Product: CR DP800-GI (HCT780X+Z / DP800+Z)

Service: Forming expertise, testing, analysis and support

Location: Newton Aycliffe, UK

After experiencing high reject rates on press parts with steel from four different suppliers, our long-time customer Gestamp called in our CTS experts who turned to their R&D colleagues who pinpointed the stamping process, in particular the punch clearance, as the issue. After a series of trials, a ‘sweet spot’ was found, resulting in less waste and reduced downtime, along with improved throughput.

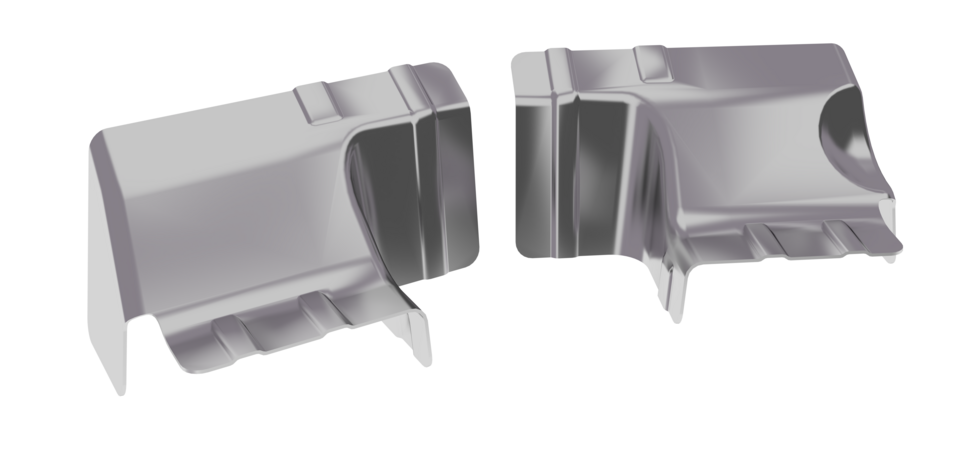

Advanced High Strength Steels (AHSS) such as our CR DP800-GI, engineered for enhanced strength and good formability, require specifically-defined cutting clearances to maintain cut edge quality.

If an edge splits when stretched, it has to be scrapped. Gestamp, working on inherited tooling at their new plant in Newton Aycliffe, was experiencing average reject rates of 22%. After observation, and satisfied that the problem lay not with the material but the process, our R&D experts pinpointed the 9% punch clearance between the die and the stamp as the issue.

Working closely with Gestamp, we carried out trials using a range of clearances from 10-14%, making adjustments to the second stage trim tool and focusing on an area with significant split rates. A 12% clearance proved to be the ‘sweet spot’ and trim tools were re-worked accordingly. The scrap rate reduced to 0.001%.

The high level of support from our CTS and R&D teams in both materials and manufacturing helps customers such as Gestamp to save time, money and energy – reducing indirect CO2 in their facilities and products.

EN-Automotive-Contact-General sales TSUK

Enquiries and customer services

Please contact us for further information, questions and enquiries.

Tata Steel

Llanwern Works

Newport

NP19 4QZ

United Kingdom