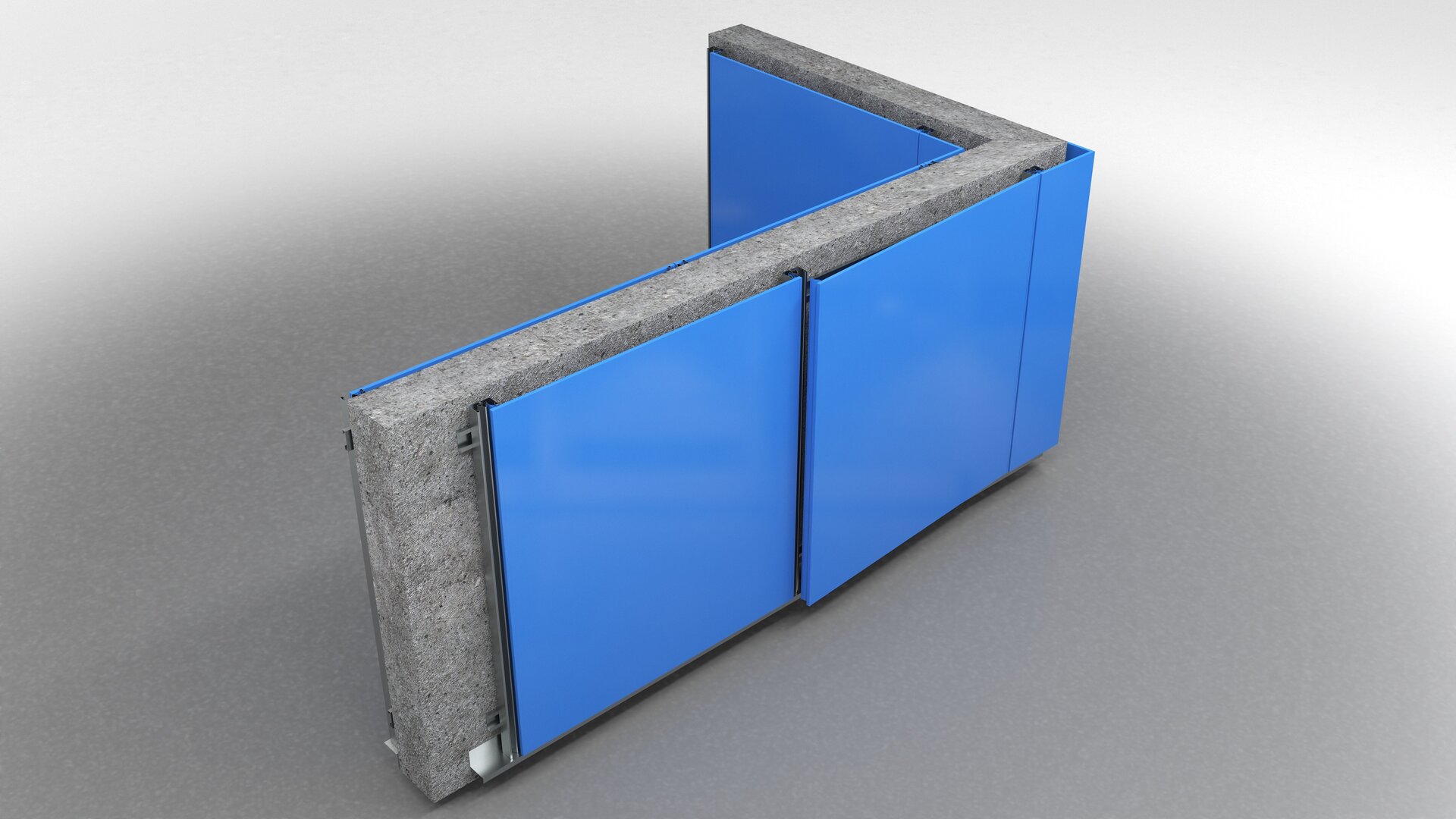

Trimawall® demountable, modular internal walling system

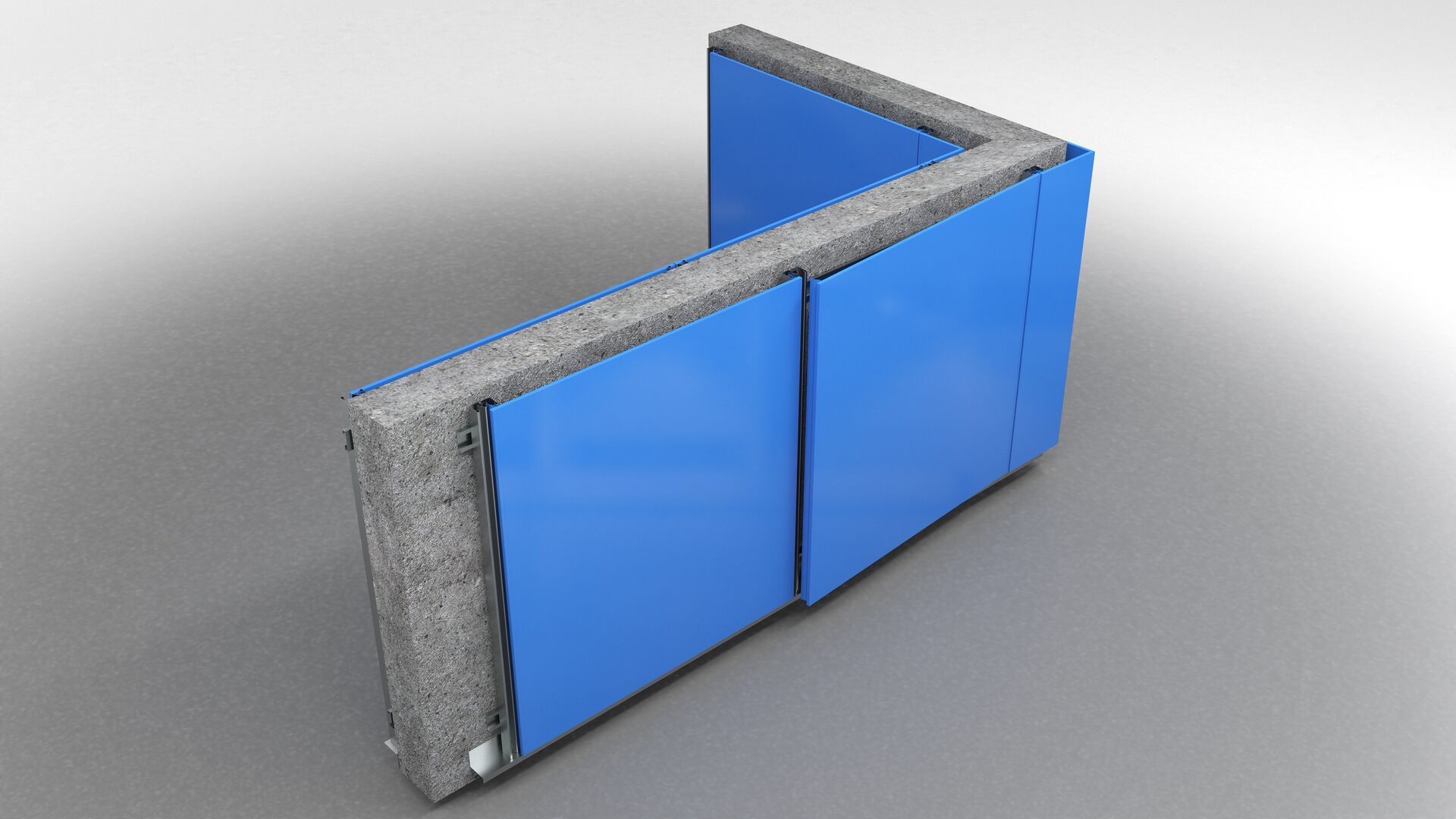

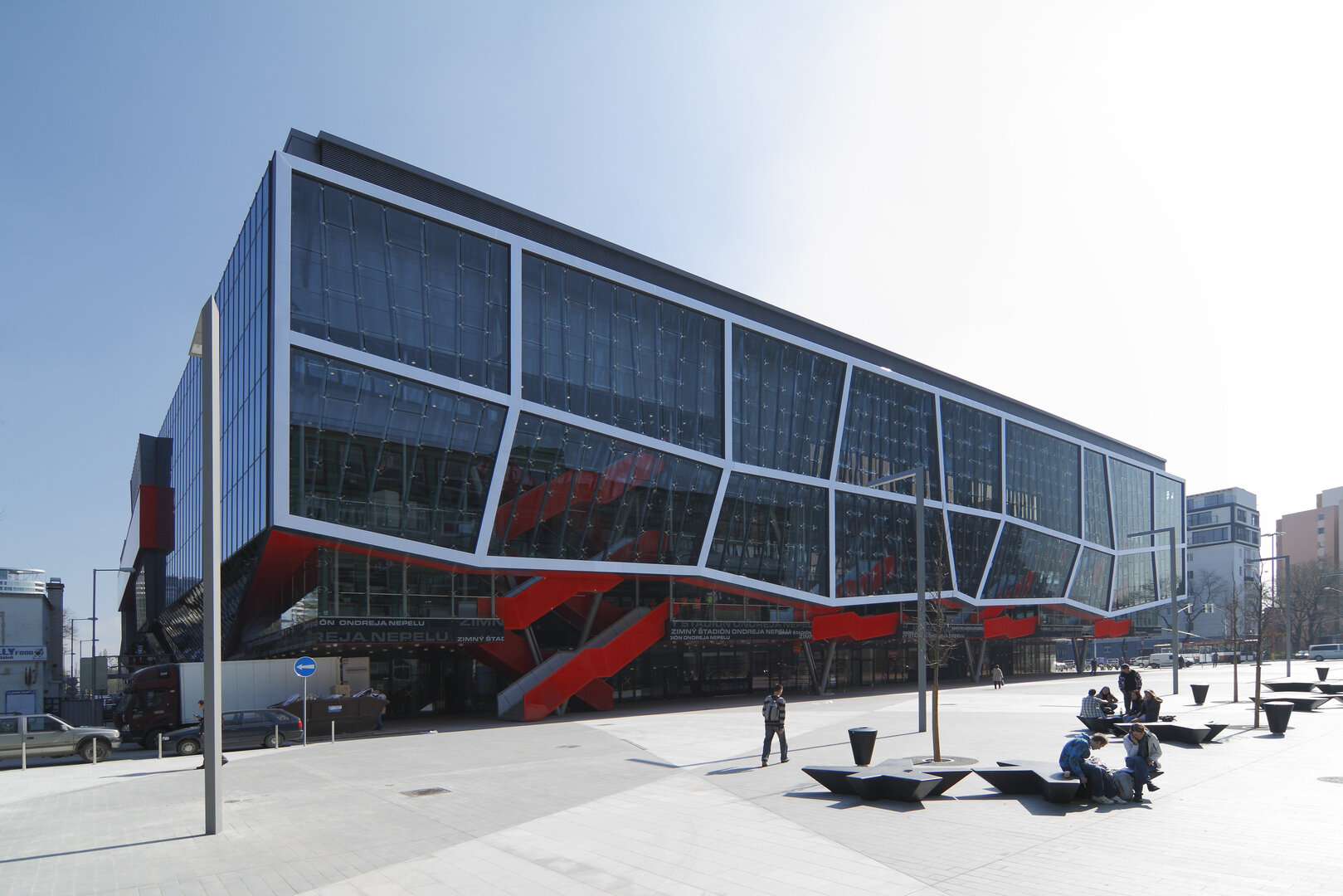

Building Systems UK's Trimawall® demountable, modular internal walling system is a DfMA solution that can radically change the speed, safety and environmental impact of construction. Hygienic, strong and versatile, the high performance pre-finished panels are delivered as a kit of parts minimising on site waste and processes, facilitating on-time, on-budget delivery of projects.

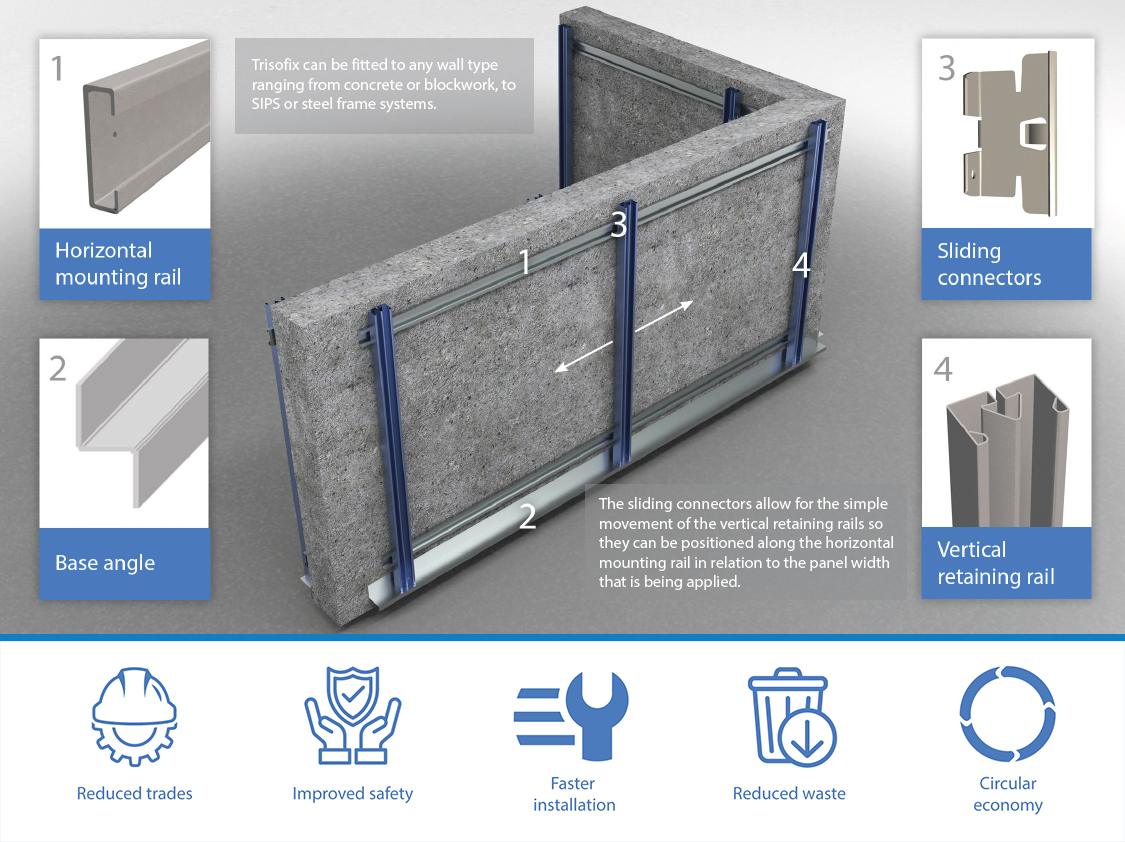

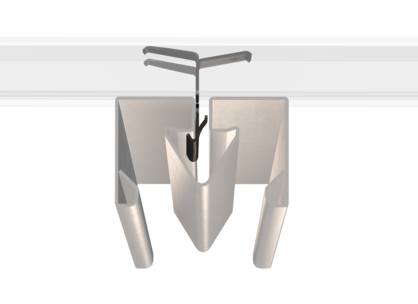

Trimawall utilises the patented Trisofix® universal mounting system giving the ability to change and reconfigure living and working spaces during the life of the building asset. Developed for construction in partnership with Reform Systems Ltd, Trisofix® is designed for demountability and reuse allowing for dust and noise free installation and simplified adaptation of spaces.

EN-Construction-Product-Fast-Fit-Advantica-control

EN-Construction-Product-Fast-Fit-Overview

This revolutionary systems transforms the way in which future buildings address fire safety and circularity.

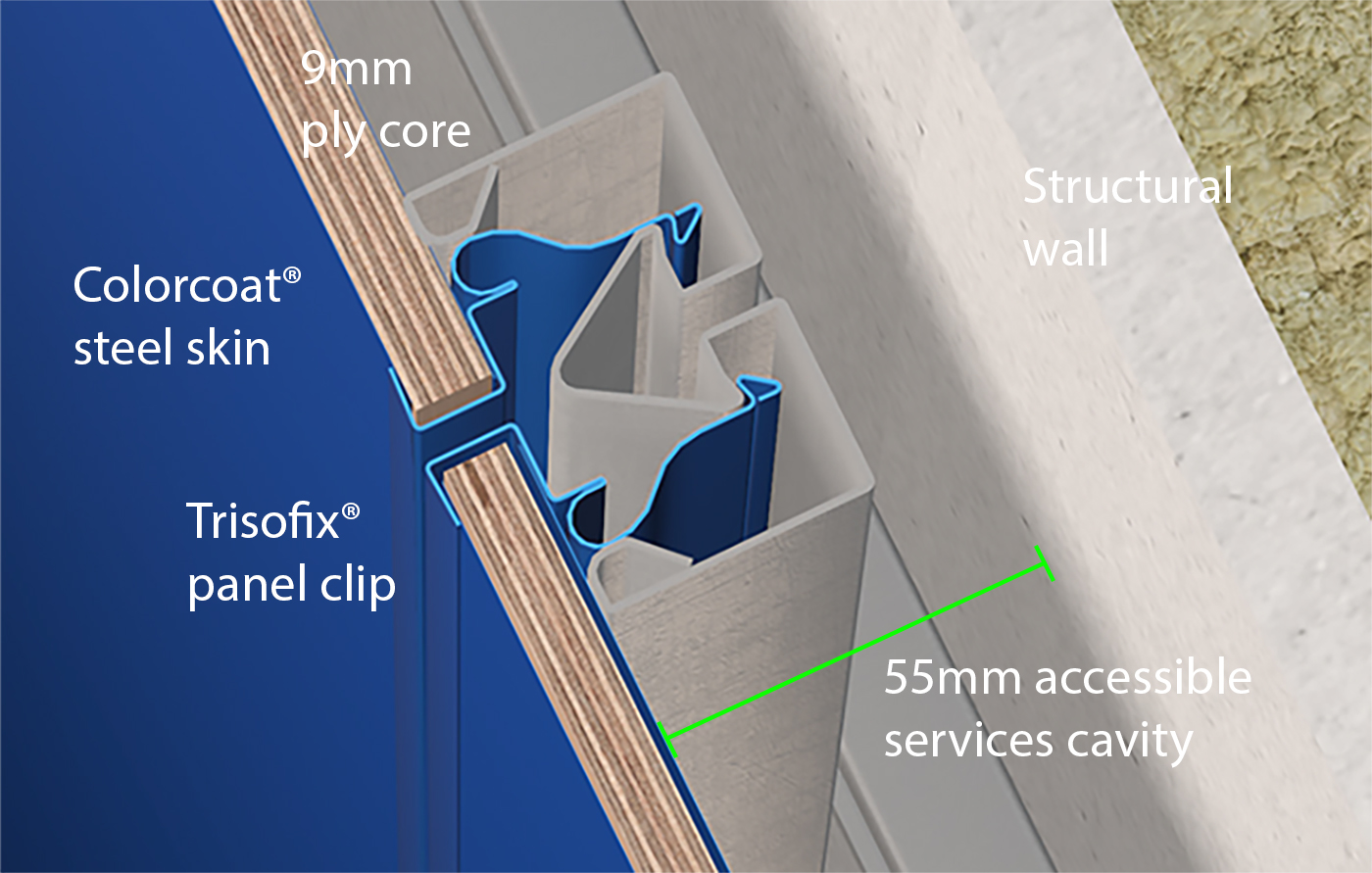

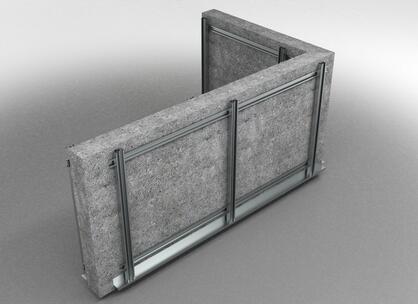

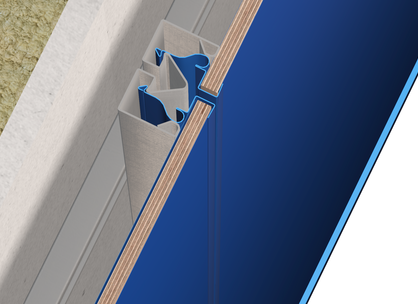

Trimawall® with it's Trisofix® universal mounting system can be mounted over a wide range of structural wall types creating an accessible service cavity finished with a high performance pre-finished panel. By removing the need for additional pattress boards and reducing penetrations into the main fire compartment Trimawall® ensuring as built integrity in the event of a fire.

The demountable panels and accessible services cavity simplifies and speeds up the complete M&E installation making it a great choice for large building projects such as schools, hospitals, offices and housing schemes, where quick build times and future adaptability are of particular importance.

A strong and versatile alternative to traditional building materials. The Trimawall® interior panels are supplied with a choice of Colorcoat® pre-painted finishes, requiring no wet trades to complete and eliminating on-site plastering dust.

Trimawall® is a DfMA (Designed for Manufacture and Assembly) solution that helps tackle the skills and supply chain shortages within construction, unlocking additional capacity both off-site and on-site, facilitating on-time, on-budget delivery of projects.

EN-Construction-Product-Fast-Fit-Benefits

Future proofing buildings

The versatility of Trimawall® and its individually demountable panels creating an accessible service cavity means that it can be installed, demounted and then reconfigured to adapt to changing needs of the building users.

Trimawall® delivers benefit for both construction companies and end clients

For Healthcare: The Advantica L Control coated panel and wrapped edges, offer a robust surface approved by Bioquell for vapour cleaning with their Hydrogen Peroxide solutions. Building Systems UK has also partnered with Construction Specialities to create a range of Acrovyn skinned panels to create hygienic, healthcare approved walls in a wide range of colours and patterns.

For Schools: The durable magnetic Colocoat® walling is perfect for classroom displays, maintaining its appearance term after term, avoiding the expense and disruption of regular repainting.

For Commercial Offices and Retail: The individually demountable panels allow spaces to be adapted to changing occupier requirements, with panels relocated, reconfigured or replaced, enabling building & brand refreshes to be conducted overnight.

For Volumetric builders: With a systemised set of pre-cut, pre finished panels, off-site value can be maximised while factory productivity & output is increased.

For Traditional construction: Having a single pre-finished panel, rated to severe duty deflection & patressesing standards helps to minimise deliveries to site, on site waste and the need for wet trade finishing, vastly simplifying crew logistics and condensing build schedules

For M&E Installers: The pre-cut panels and accessible service cavity eliminates the hassle of threading and wall rework, reducing on site errors, ensuring detail consistency, and facilitating a much faster, simpler M&E install.

EN-Construction-Product-Fast-Fit-Sustainability

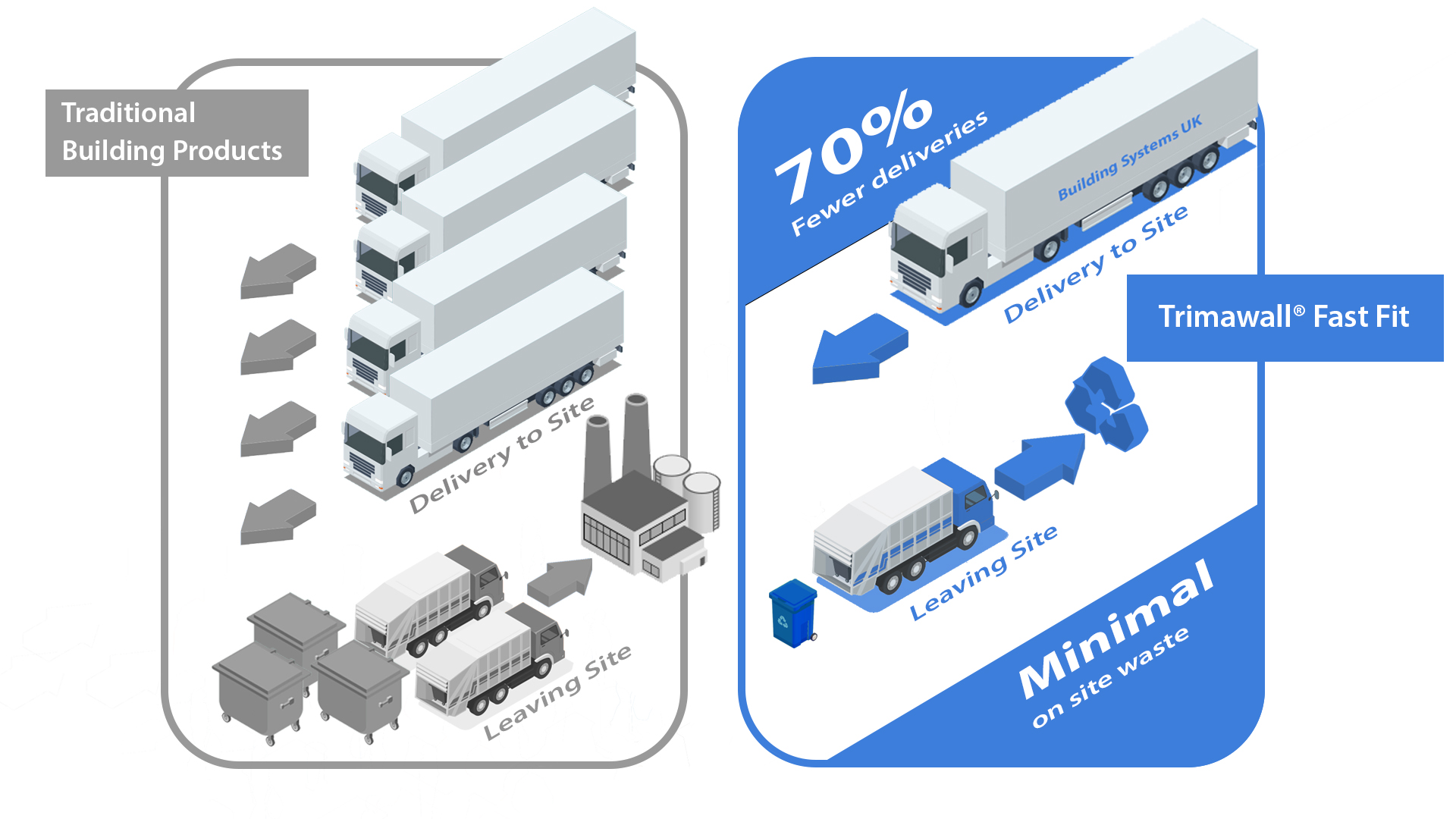

Trimawall® is manufactured and delivered as a kit of parts to minimise the environmental impact during construction and fit out. This avoids over ordering, reducing deliveries, on-site cutting waste, and snagging.

The 11mm thick Trimawall® panel incorporates a hygienic pre-finished front skin as part of a robust steel composite that provides all the requisite pattress strength required for Severe Duty rated walls.

Being delivered to site already cut to size with the Trisofix® panel clips pre-installed, Trimawall® typically requires 70% less material deliveries than traditional pattress and plasterboard construction, all but eliminating the on-site waste commonly associated with cutting, plastering and finishing internal walls.

EN-Construction-Product-Fast-Fit-Kit of parts

Hygienic, strong and versatile

Trimawall® is a steel skinned composite panel with a ply core offering exceptional strength and durability.

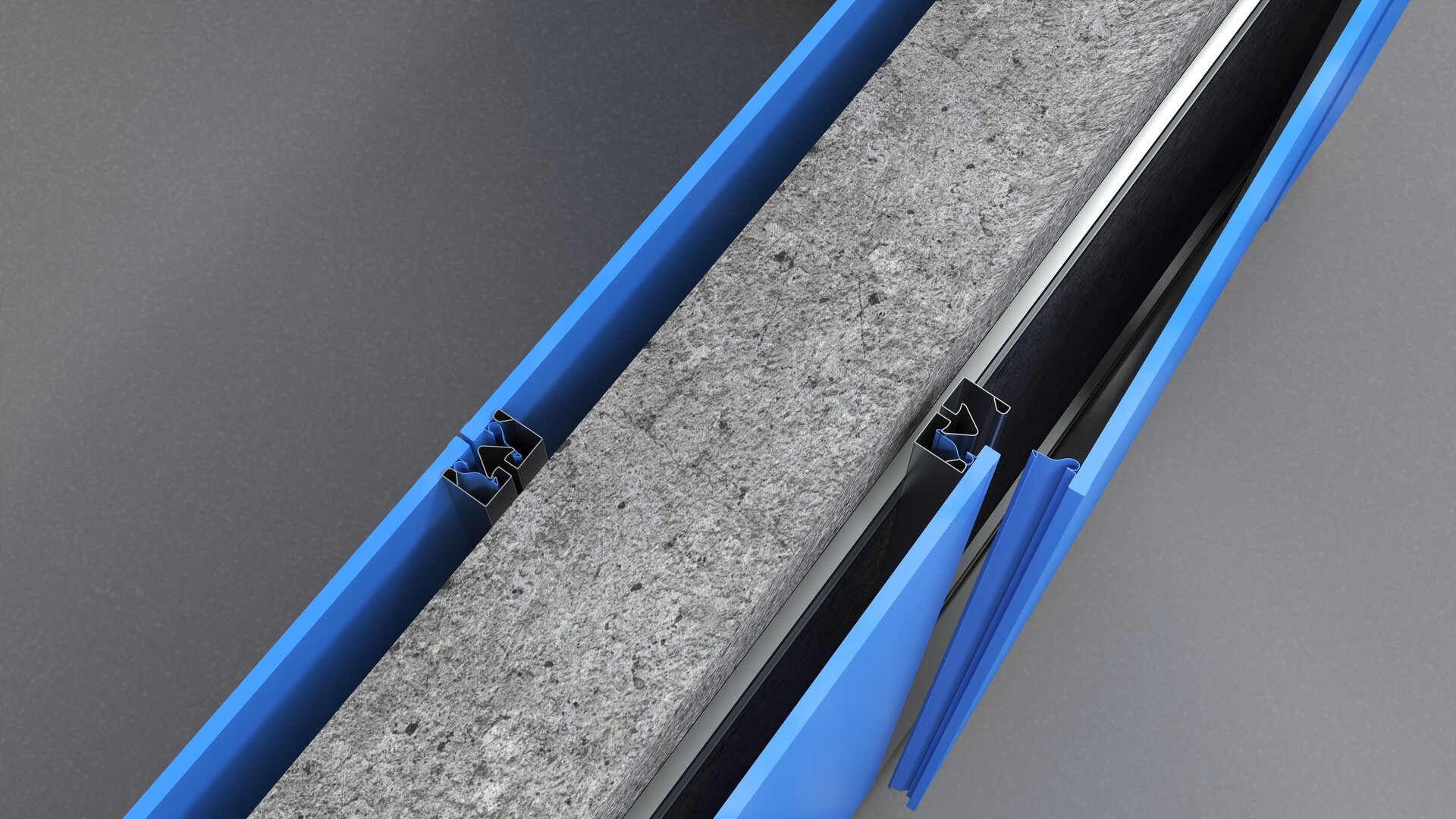

Utilising the patented Trisofix® universal mounting system a set of high grade coated steel components that fixes back to any structural wall type.

Typically Trisofix’s clip is factory fitted to Trimawall’s prefinished panels but can also be fitted on site offering hybrid functionality and flexibility for installers.

EN-Construction-Product-Fast-Fit-Tool-Free

Fast & efficient wall finishing

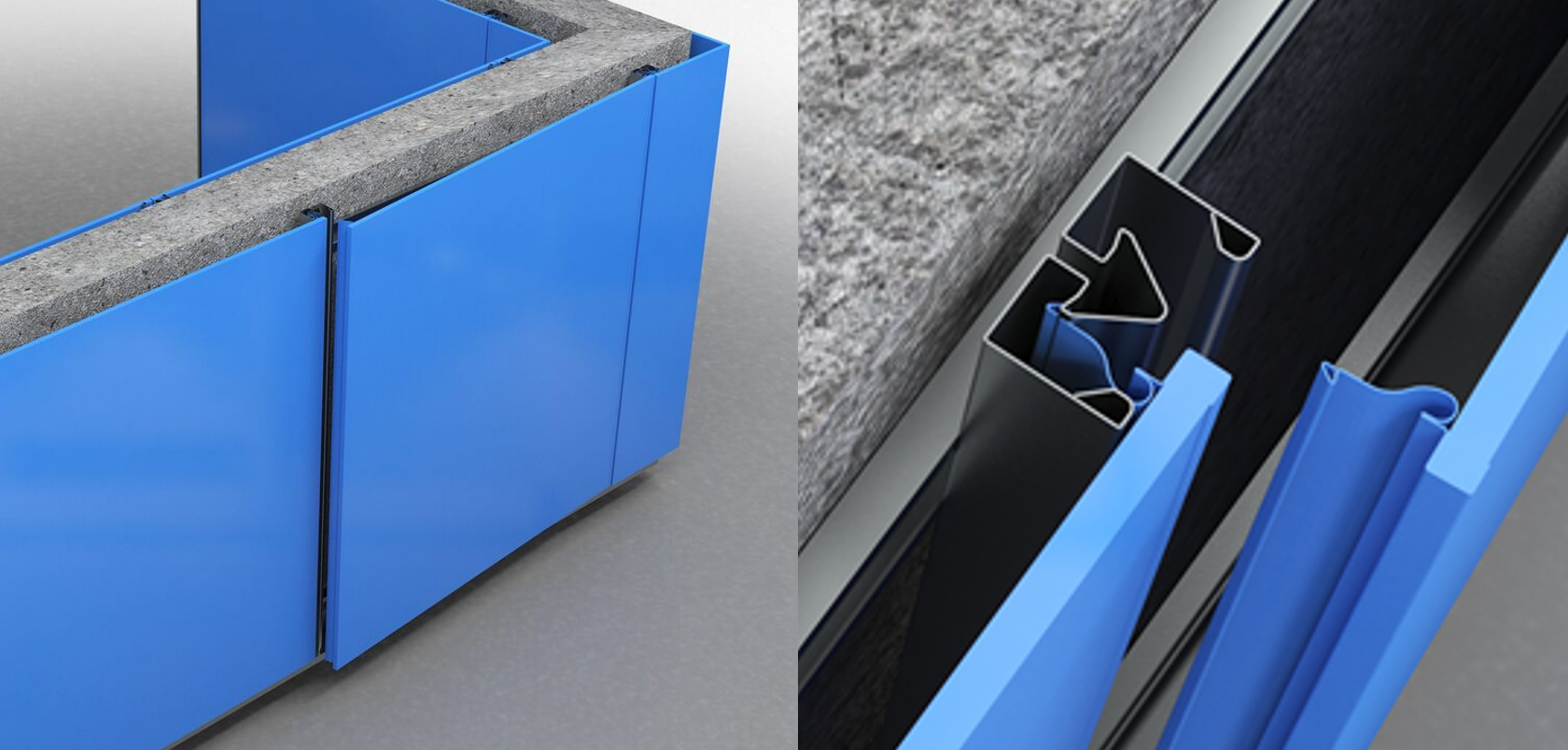

Trimawall’s steel skinned composite panels are mounted using the Trisofix® patented clip system that is pre-applied to the vertical edges of the composite sheet in our factory.

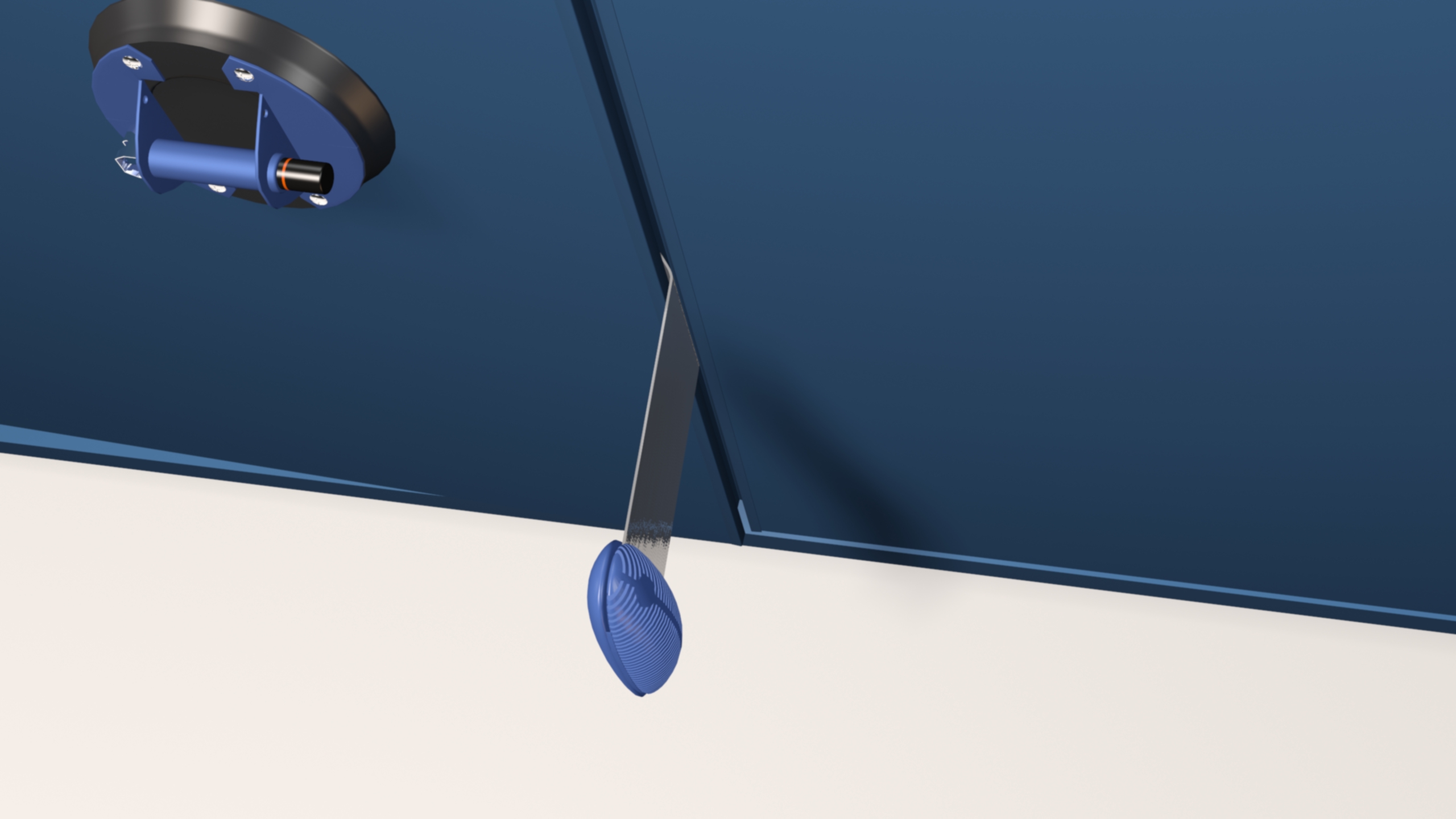

On-site, the panels can typically be lifted with vacuum lifters and push fitted by a 2-person installation crew. With the pre-finished panel requiring no additional wet trade finishing Trimawall® helps simplify and condense the total fit out and finishing process.

Individually demountable panels

Trimawall® Fast Fit’s panels can be individually demounted by a 2 person crew using vacuum lifters and the Trimawall® demounting tool. The panels can be demounted & reinstalled multiple times without compromising performance or aesthetics. Not only does this allow for easy access to the M&E services within the cavity for maintenance or upgrading, but it allows panels to be relocated, reused, replaced to help reconfigure and enhance buildings over time.

Trimawall® demountable tool guide

Click here to watch

EN-Construction-Product-Fast-Fit-downloads

Find related downloads below for your project specification: