Leading manufacturer of steel building products Catnic has launched Catnic SolarSeam, an innovative photovoltaic solution for standing seam roofs that has been engineered to deliver exceptional performance without compromising on aesthetics.

Catnic SolarSeam consists of a flexible solar laminate bonded to the popular Catnic Urban standing seam roofing panel, delivering efficient renewable energy without the traditionally highly visible frames. Catnic SolarSeam panels can be installed on roof pitches down to five degrees for true design flexibility. Supplied as a complete kit of parts, including the panels, flashings and fixings, SolarSeam is simple to order and straightforward to install.

Catnic SolarSeam uses Copper Indium Gallium Selenide (CIGS) solar technology. The MCS Certified low-profile CIGS cells are made up of multiple diodes, meaning they have excellent ambient light performance, and unlike traditional monocrystalline panels, have high shade tolerance. This means that more energy is captured, even on cloudy days, and homeowners are not restricted to installation on south facing roofs. In fact, with monocrystalline panels shading reduces energy production by as much as 80%, while for CIGS panels it is as little as 10%. CIGS cells are also lighter, more flexible and more resistant to damage, cracking and physical impacts.

“Catnic SolarSeam provides an ideal solution for new and refurbishment projects that not only delivers excellent solar performance but also allows design flexibility and uncompromised aesthetics."

It also provides further sustainability benefits as Catnic SolarSeam’s CIGS cells are manufactured in the UK and require significantly less energy to produce compared with monocrystalline products for a lower carbon footprint. Additionally, the Catnic Urban panel that the cells are bonded to, is also made in the UK and has BES 6001 Responsible Sourcing certification and a BRE A+ rating, demonstrating it has the lowest overall environmental impact. All this makes Catnic SolarSeam ideal for environmentally conscious customers.

With fire performance an essential consideration, the solar panel when bonded to a Catnic Urban panel has been tested in accordance with CEN/TS 1187-4 and classified as BROOF(t4) for external fire performance, the highest rating possible, with minimal flame spread and no fire penetration for at least 60 minutes.

For customer peace of mind, Catnic SolarSeam is supplied with multiple guarantees. There is a 25-year Confidex® Home Guarantee on the Catnic Urban roof substrate as well as a 10-year solar product guarantee. The performance of the solar is also covered by a 25-year guarantee.

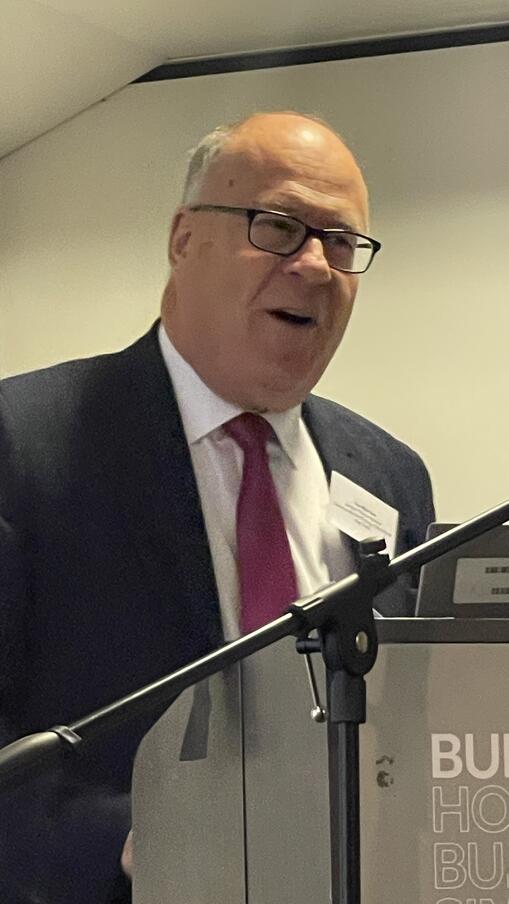

At a launch event at the Building Centre in London, David Hanson, Managing Director of Catnic commented: “With the target for a 68 percent reduction in greenhouse gas emissions from 1990 levels by 2030, renewable energy, and solar in particular, has never been more important. Recent indications from the Government suggest that solar panels could be mandatory on all new homes from 2027 and with a target to build 1.5 million new homes within this parliamentary term, the expansion of residential solar could be considerable.

“Catnic SolarSeam therefore provides an ideal solution for new and refurbishment projects that not only delivers excellent solar performance but also allows design flexibility and uncompromised aesthetics. It also represents an opportunity for roofing professionals with skills in the installation of standing seam roofing to expand their offering to customers.”

For more information on Catnic SolarSeam, visit www.catnic.com.

About Tata Steel UK

- The Tata Steel Group has been named one of the most ethical companies in the world, and is among the top producing global steel companies with an annual crude steel capacity of 34 million tonnes.

Tata Steel in the UK has the ambition to produce net-zero steel by 2045 at the latest, and to have reduced 30% of its CO2 emissions by 2030. - In October 2024, Tata Steel ceased ironmaking at its Port Talbot site and temporarily paused steelmaking pending the construction of a 3.2Mtpa Electric Arc Furnace, due to be commissioned late in 2027 / early 2028. For that period, the business will import slab and hot rolled coil to support manufacturing and distribution operations at sites across Wales, England and Northern Ireland as well as Norway, Sweden, France, Germany and UAE. It also benefits from a network of sales offices around the world.

- Throughout 2024 Tata Steel UK has been undergoing a restructuring that will reduce the size of its workforce to around 5000 direct employees, supplying high-quality steel products to demanding markets, including construction and infrastructure, automotive, packaging and engineering.

- Tata Steel Group is one of the world's most geographically-diversified steel producers, with operations and a commercial presence across the world.

- The group recorded a consolidated turnover of around US$26 billion in the financial year ending March 31, 2025..