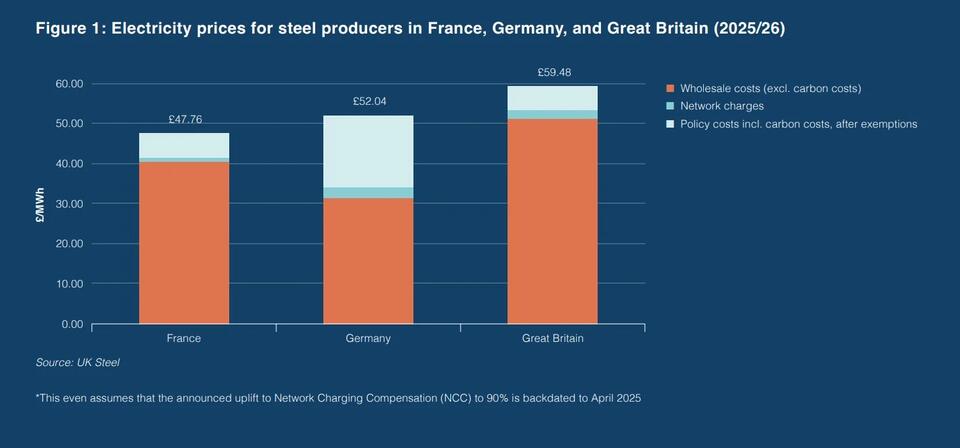

This comes despite recent UK Government steps to reduce industrial power prices.

Britain’s steelmakers are still paying millions more for electricity than our European competitors.

As Tata Steel UK and the steel industry moves towards electric arc furnaces, which use a lot of electricity, fair energy prices are now more important than ever.

UK Steel is recommending two key changes to resolve the issue:

- Introduce two-way Contracts for Difference (CfDs) for wholesale electricity, aligning UK industrial power prices with those in France and Germany.

- Ensure the uplift to 90% compensation for network charges is backdated to April 2025, avoiding another year of excessive costs for UK producers.

Commenting Gareth Stace, Director-General of UK Steel, said:

"The Government has already taken steps to tackle uncompetitive industrial power prices, which have been greatly welcomed by the industry. However, our report shows that Britain’s steelmakers are still paying millions more for electricity than our European competitors.

"The UK steel industry has a hand tied behind its back as it faces electricity prices up to 25% higher than its European competitors, let alone its global counterparts. Uncompetitive power prices pose a threat to jobs, future investment, and our Net Zero ambitions. Our report shows there is now a straightforward solution with a two-way CfD mechanism and swift backdating of network charge relief, the Government can finally eliminate the disparity in industrial electricity prices.

“The prize is enormous. By securing competitive power prices, the UK can build a modern, low-carbon steel industry that underpins growth in clean energy, infrastructure, and manufacturing for decades to come.”

READ THE FULL REPORT HERE: Industrial Electricity Prices – Barrier to growth and competitiveness

More information about the range of Tata Steel's policy asks of government can be found here: tata-steel-uk-briefing---challenges-and-opportunies-for-decarbonising,-june-2025.pdf