Kieran Butroid, Technical Advisory Engineer for welded structural hollow sections at Tata Steel UK discusses the fundamental differences in manufacturing methods, the steel quality within the two annexes of the European hot finished structural hollow section standard EN 10210, and why it is important that designers and specifiers are aware of these differences.

Hot-finished definition as per EN 10210 – the importance of understanding which Annex is applicable to ensure a full-body normalised structural hollow section

EN10210 allows for two different types of manufacture under the definition of hot-finished hollow sections, but it is important to note that they are very different in the way they perform due to the different heat treatment processes as will be discussed below.

What is hot finished? Within the Scope of ‘EN 10210-1:2006 Hot finished structural hollow sections of non-alloy and fine grain steels’ is stated as:

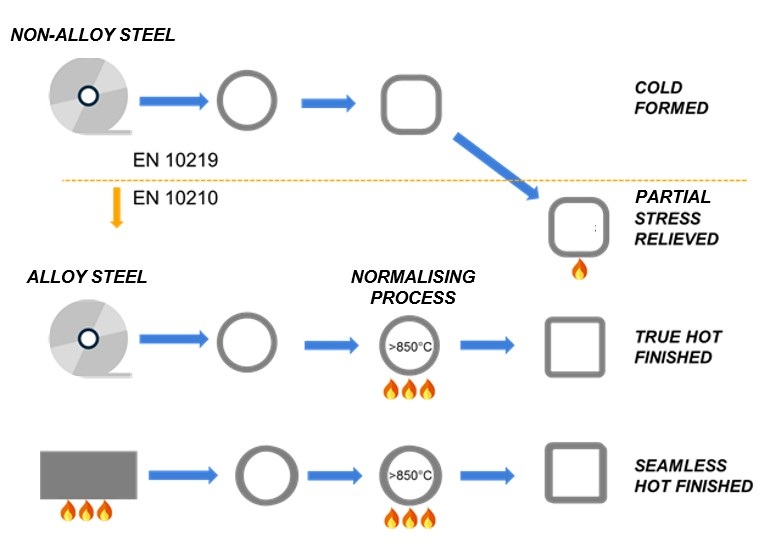

• Hot Finished - Hollow sections (1) formed hot with or without subsequent heat treatment or (2) formed cold with subsequent heat treatment to obtain the equivalent metallurgical conditions to those obtained in the hot formed product. See Fig. 1.

Fig. 1 Methods of producing hot-finished structural hollow sections

The two methods of producing hot structural hollow sections are very different not only in the manufacturing process but also the type of steel used. Therefore, within the EN 10210-1 standard, there are two annexes to match these different manufacturing routes:

• Annex A for non-alloy steels. [Typical grade S355J2H]. Tube is formed and shaped cold and then subsequently heat treated at an undefined temperature and duration.

• Annex B for alloy steels. [Typical grade S355NH such as Tata Steel's Celsius S355]. Tube is formed and shaped within a controlled normalising temperature range (circa 900⁰C).

Therefore, Annex A and Annex B are fundamentally different and will lead to different mechanical properties.

Annex A

The market recognised EN 10210 S355J2H grade falls under EN 10210-1 Annex A for non-alloy steel and therefore the section is initially formed cold and subsequently heat treated giving the minimum requirements set out in EN 10210 and then utilised as a hot structural hollow section.

However, heat treating the hollow section steel below the normalisation temperature, does not remove all inherent stresses caused by the initial cold forming process, and therefore results in a variable grain structure and inconsistent mechanical properties, both in the weld line and corner regions in square and rectangular hollow sections.

It is important to note that the statement ‘heat treatment’ is not defined as no specific temperature, or duration, is stated in the EN 10210 standard, so the amount of stress relief is an unknown parameter.

Annex B

The typical structural grade given in EN 10210-1 Annex B is S355NH. EN 10210-1 Annex B uses alloy steels that have specific alloy elements and therefore structural hollow sections are able to be shaped and formed at normalising temperature of circa 850⁰C – 950⁰C without significant loss of yield strength, which is one of the reasons why Annex A steels cannot be normalised.

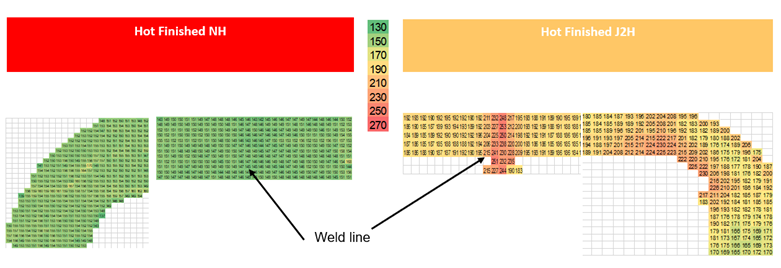

The normalising manufacturing process recrystallises the steel to create a fully austenite uniform fine grain structure resulting in stable mechanical properties throughout the entire section, including the weld line and corner regions for square and rectangular hollow sections. See Fig. 2. This enables easier fabrication, welding, and manipulation with more predictable performance in use.

Typically, physically forming the final tube shape at normalising temperature results in a tighter external corner profile for square and rectangular hollow sections which also enables good preparation for welding compared to an Annex A cold-formed, heat-treated hollow section, which, as is the case with cold formed hollow sections, have much larger external corner radii due to tube being initially cold-formed.

Fig. 2 The colours on the images represent the results of micro-hardness tests on two EN10210 sections, both with a specific minimum yield strength of 355 N/mm2 - Annex B (left graphic) and Annex A (right graphic). This shows the variation in the hardnesses through the cross section that are still apparent within an Annex A EN 10210 structural hollow section, relating to variations in residual stresses and grain structures.

Due to Annex B normalised steel (S355NH) having uniform, stable mechanical properties, this also improves the steel ductility with a minimum charpy impact, stated in the standard, of 40J @ -20⁰C compared to Annex A (S355J2H) 27J @ -20⁰C.

Weldability and chemical composition

For structural applications, structural hollow sections also require a 3.1 test certificate for batch-specific steel traceability and physical testing.

For EN 10210 (J2H) Annex A steels, the standard shows no requirement on the 3.1 certificate for a full list of steel elements and therefore it may not be clear if the steel is either heat treated or fully-killed and even if it is claimed (EN 10210-1 Annex A Table A.1 states that J2H should have ‘FF’ aluminium deoxidation) this may not be clear on the 3.1 certificate how this has been achieved.

Conversely, for specific 3.1 certification for Annex B steels (such as S355NH) the standard requires a full element list for the alloy steel, including nitrogen-binding elements and aluminium content (for ‘GF’ deoxidation as stated in EN 10210-1 Annex B Table B.1).

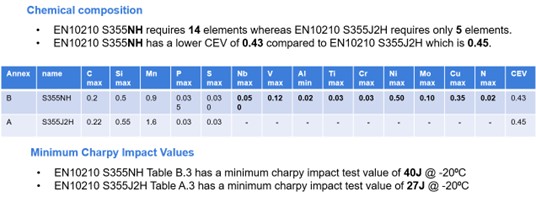

The standard also dictates a CEV value, for Annex B S355NH, the CEV value is lower than of Annex A S355J2H with 0.43% Max and 0.45% Max respectively. Lower CEV values enable for better weldability of the steel as it reduces the formation of a brittle microstructure during the welding phase. See Fig. 3.

Fig. 3 Stated chemical composition requirements for Annex A and B respectively. Only Annex B requires a full statement of elements as standard.

It is worth noting that a steel that meets Annex B can also be certified as J2H, but not the other way round.

In summary, this article explains the different types of steel quality used within the two separate annexes in EN 10210 and engineers and specifiers need to be aware of what is actually being specified when allocating a hot finished grade to a design. It would also be prudent to ask questions of the manufacturer such as what temperature is used to heat treat the tube to understand whether it has been processed under Annex A or Annex B.

If you require any further details or would like a CPD on this subject, please contact Kieran either by email kieran.butroid@tatasteeleurope.com or telephone 07920 835317.