Tata Steel UK

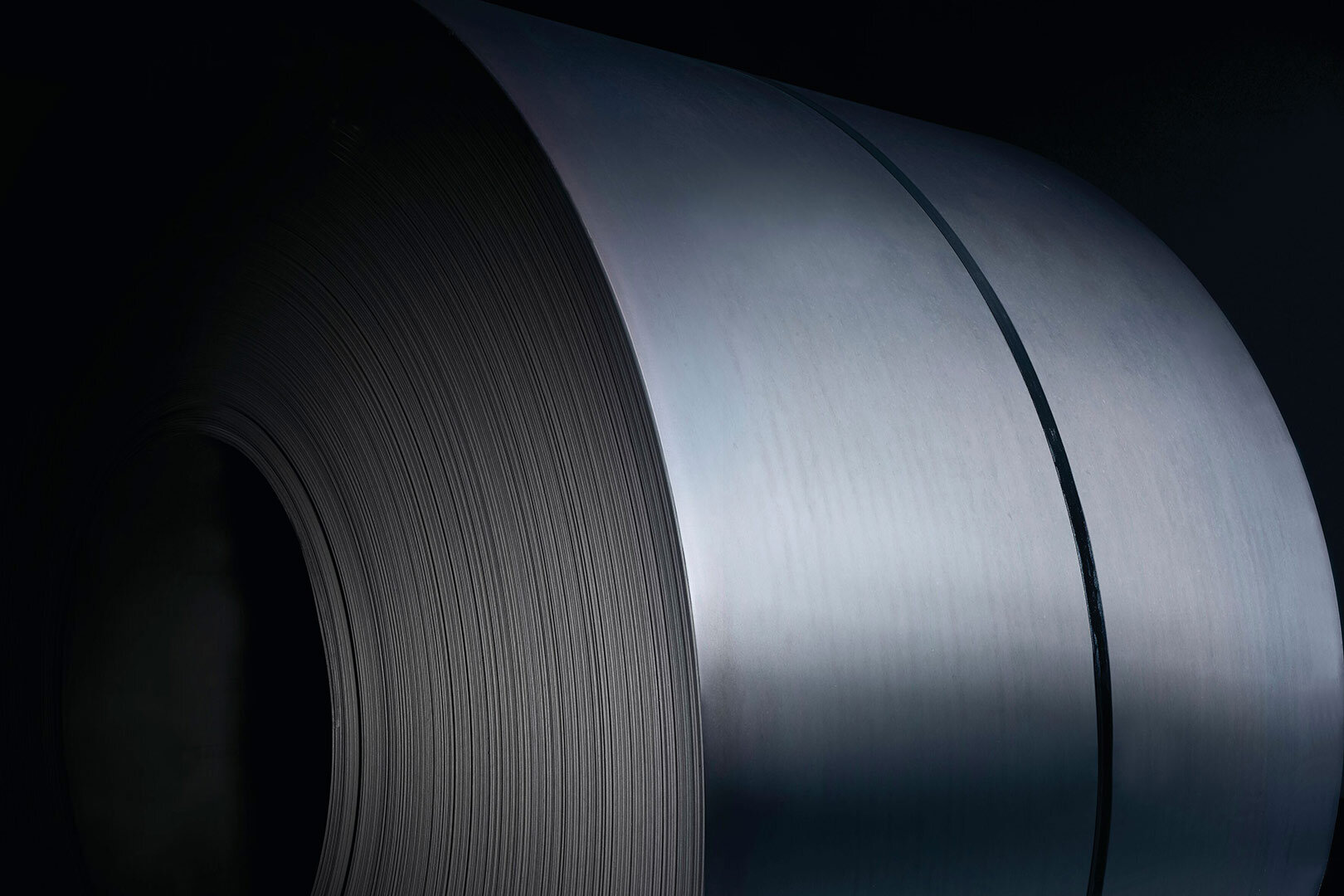

Cold-rolled

Tata Steel UK no longer produces cold-rolled annealed coil.

However customers can still purchase cold-rolled products through our service centres. These can be purchased as wide coil, pressed blanks, slit coil, sheets, sheared blanks and tailor welded blanks. Customers can also purchase wide coil from Tata Steel Netherlands. For further information follow the links below.

0%

Tata Steel

Cold-rolled steel suppliers

EN-TSN-Engineering-Product-Cold-rolled

Tata Steel Nederland (Engineering)

We offers a comprehensive range of cold-rolled batch annealed products

EN-TSN-Automotive-Product-Cold-rolled

Tata Steel Nederland (Automotive)

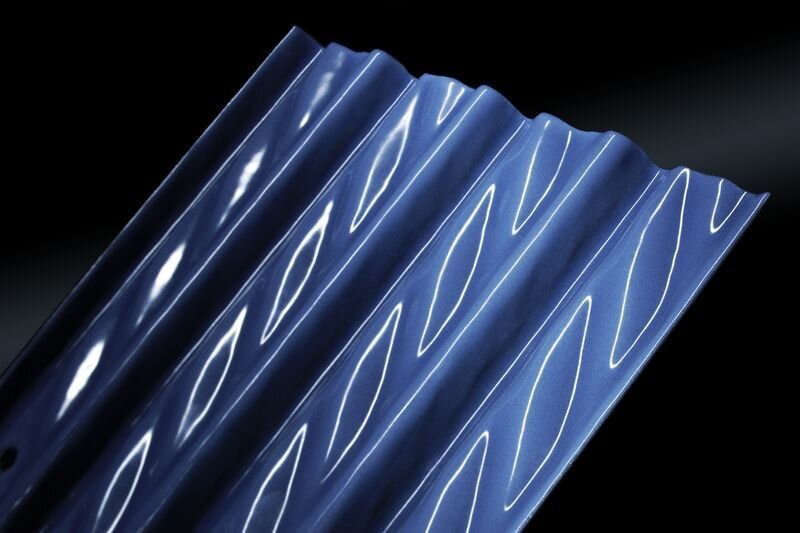

We can tailor our offer to meet your precise requirements for formability, strength, surface finish or flatness.

EN-TSN-Service Centre-Layde Narrow Strip

Layde narrow cold-rolled strip

Our cold-rolling process produces materials with tighter mechanical properties, tighter thickness tolerances and better surface quality.

Off